The frequency f determines how many times each edge of the initial icosahedron is subdivided. Subdivide each triangular face into f2 triangles., eg. for f=4, each triangle is divided into 16 smaller triangles.

Polycarbonate |

Acrylic |

|

|

Considering these factors, acrylic is often the preferred material for secondary glazing, while polycarbonate is widely used for roofing in structures like bus shelters and conservatories due to its exceptional durability.

Sheet materials are available in various finishes, including reflective coatings, opaque options, and solid colors, providing flexibility in design and functionality.

It’s important to note that once the dome is constructed, individual panels can be replaced, modified, or repaired as needed. Additionally, the entire structure can be dismantled and reassembled at a different location, offering adaptability and long-term usability.

Using 3mm or 4mm sheet material strikes a balance between cost-effectiveness and flexibility, while also providing sufficient strength and durability for most applications. For specific needs, you might opt for 1mm polycarbonate for an ultra-flexible dome or 5mm acrylic for a storm-resistant shelter. However, with thicker materials, the reduced flexibility should be taken into account.

Material thickness also impacts the natural air gap, as outlined below. When incorporating features such as windows and door frames, the chosen thickness will influence design choices. Thinner materials may require additional support for windows, and door frames might need reinforcement to maintain structural integrity. Additionally, the weight of the material is a crucial factor to consider in your overall design.

As an example: a single `Pentagon` piece of the 4m dome, in 4mm Acrylic weighs 970g. A full dome will require 166 * ~970g, which equates to ~161Kg.

For a 7m dome, consider using 4mm sheets for the lower sections and 3mm sheets for the middle and upper parts. This approach reduces overall weight and cost.

The dome uses overlapping sheet panels, with upper panels overlapping lower ones to direct rainwater outward and prevent leaks.

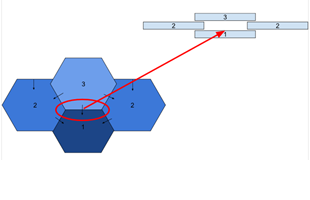

In a 3-frequency dome, each panel is offset by about 10 degrees from its neighbor. With appropriately flexible sheet material, this offset can be accommodated as the material flexes over its width, allowing panels to align on the same horizontal plane. Ensure your chosen material can flex adequately to minimize stress on the structure and fixings.

The dome structure features joints where three faces meet, with gaps sometimes forming between the top and bottom panels due to the overlapping design. These gaps can be filled using shims of the same material, secured with existing bolts. Angular gaps are usually left open for ventilation, as the dome doesn’t need to be airtight.

The base must be level to ensure proper alignment; any skew in the first layer will misalign holes as the dome rises. Construction begins at ground level, adding overlapping panels layer by layer. At least two people are recommended for assembly above waist height for ease of securing bolts.

Nuts and bolts should remain 3/4 tightened during assembly to allow flexibility. As the dome nears completion, a ladder may be needed to access the top, and the doorway should be finalized before attaching the top pentagon.